Deionization Deionization (DI), and ongoing electrodeionization (CEDI) are helpful methods of improving the chemical top quality characteristics of drinking water by eliminating cations and anions. DI devices have charged resins that call for periodic regeneration with the acid and base. Commonly, cationic resins are regenerated with possibly hydrochloric or sulfuric acid, which switch the captured positive ions with hydrogen ions. Anionic resins are regenerated with sodium or potassium hydroxide, which swap captured unfavorable ions with hydroxide ions.

Extensive range of Chemokine and Histone products with worldwide transport and online savings obtainable.

The item complies Using the test, if colonies are usually not existing or In the event the confirmatory identification tests are unfavorable.

It is difficult with the maker to justify the release of a product filled aseptically that fails an initial sterility test with no determining specific problems related to the controls useful for the sterility test.

Other steam characteristics not in-depth during the monograph, in particular, the existence of even compact portions of noncondenseable gases or the existence of a superheated or dry condition, may be critical for programs for instance sterilization. The big release of energy (latent warmth of condensation) as h2o changes within the gaseous to your liquid point out is The true secret to steam's sterilization efficacy and its efficiency, generally speaking, like a warmth transfer agent. If this section change (condensation) isn't allowed to happen as the steam is extremely sizzling and in a persistent Tremendous heated, dry state, then its usefulness can be very seriously compromised.

The pH attribute was finally recognized to become redundant for the conductivity test (which provided pH as an element of the test and specification); hence, pH was dropped as a separate attribute test.

It helps to figure out the right way of sterilizing the Uncooked products and drinking water used to make various products.

as producing no drastically interfering fuel chromatography peaks. Referenced monographs specify applying this water since the solvent for normal and test Answer planning for your Organic and natural risky impurities test Guide-Cost-free Drinking water— This drinking water is applied to be a transferring diluent for an analyte inside a Guide

The microbial limit test of biological medications involves assessing the microbial contamination existing in the ultimate drug item. Organic medicine, particularly All those derived from Organic sources or produced employing biotechnological processes, are prone to website microbial contamination during manufacturing, packaging, or storage.

It should be identified that there is no single method that may be effective at detecting most of the probable microbial contaminants of the drinking water program. The methods used for microbial checking really should be able to isolating the numbers and types of organisms that were deemed substantial relative to in-procedure system Manage and product impression for each particular person process. Various requirements should be thought of when picking out a method to watch the microbial content of a pharmaceutical h2o program.

Identical Restoration between the test group along with the peptone team demonstrates enough neutralizer efficacy; related recovery among the peptone group as well as the viability group demostrates ample neutralizer toxicity.

It is assumed On this discussion that the test sample can be filtered. If it's important to solubilize the test sample, the consequences of the solubilization method on viable microorganisms has to be decided. This example can occur when testing ointments, suspensions, or other articles or blog posts.

Microbial contamination can take place in numerous components of drug creation process which include raw and auxiliary products, water, air, workshop gear and packaging resources. To forestall air pollution, corresponding actions shall be formulated here to bolster sanitation administration to guarantee environmental sanitation, substance sanitation, method sanitation, plant sanitation and personnel sanitation in drug manufacturing.

The chemical attributes listed in these monographs need to be regarded as a set of minimum specifications. Extra stringent specifications may very well be wanted for a few applications to ensure suitability for unique employs. Standard advice on the right programs of these waters is located in the monographs and is also further stated In this particular chapter.

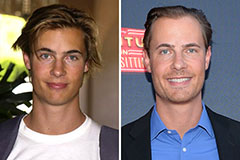

Erik von Detten Then & Now!

Erik von Detten Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now! Erika Eleniak Then & Now!

Erika Eleniak Then & Now!